|

One common

application for Microsoft is in situ microstructure replication for

checking metallurgical quality, heat treatment and creep damage. For

many years replica systems based on Acetate films have been used for

this purpose. These methods are difficult, inherently unreliable and

operators need special training and certification. Duplex

stainless Steel Oilfield Components. |

||

|

|

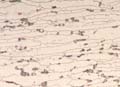

x400 |

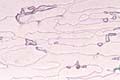

x1000 |

|

Sigma Phase adjacent to a weld in a duplex stainless steel. (Microset 101 MICRO replica). |

||

| |

Click button to read a case study Creep damage in low alloy steels |